Some Notes on Being a Good Gearman and a Good Gear Company

May 18, 1993

I. ALWAYS BE A STUDENT.

Before all else, you must have and continue to acquire knowledge about gears. Your company ought to join the American Gear Manufacturers Association (AGMA) if not already a member so that you may avail yourself of an enormous amount of information about all aspects of gears and take advantage of techniques, processes as well as marketing and legislative activities that affect our industry.

II. QUALITY IS KEY.

Always consider your customers’ requirements as minimum. Happy is the customer who receives gears noticeably better than his print requirements. Monitor the quality of your work, retain records of how and with what you produced your gear and strive to improve your performance every time the job repeats.

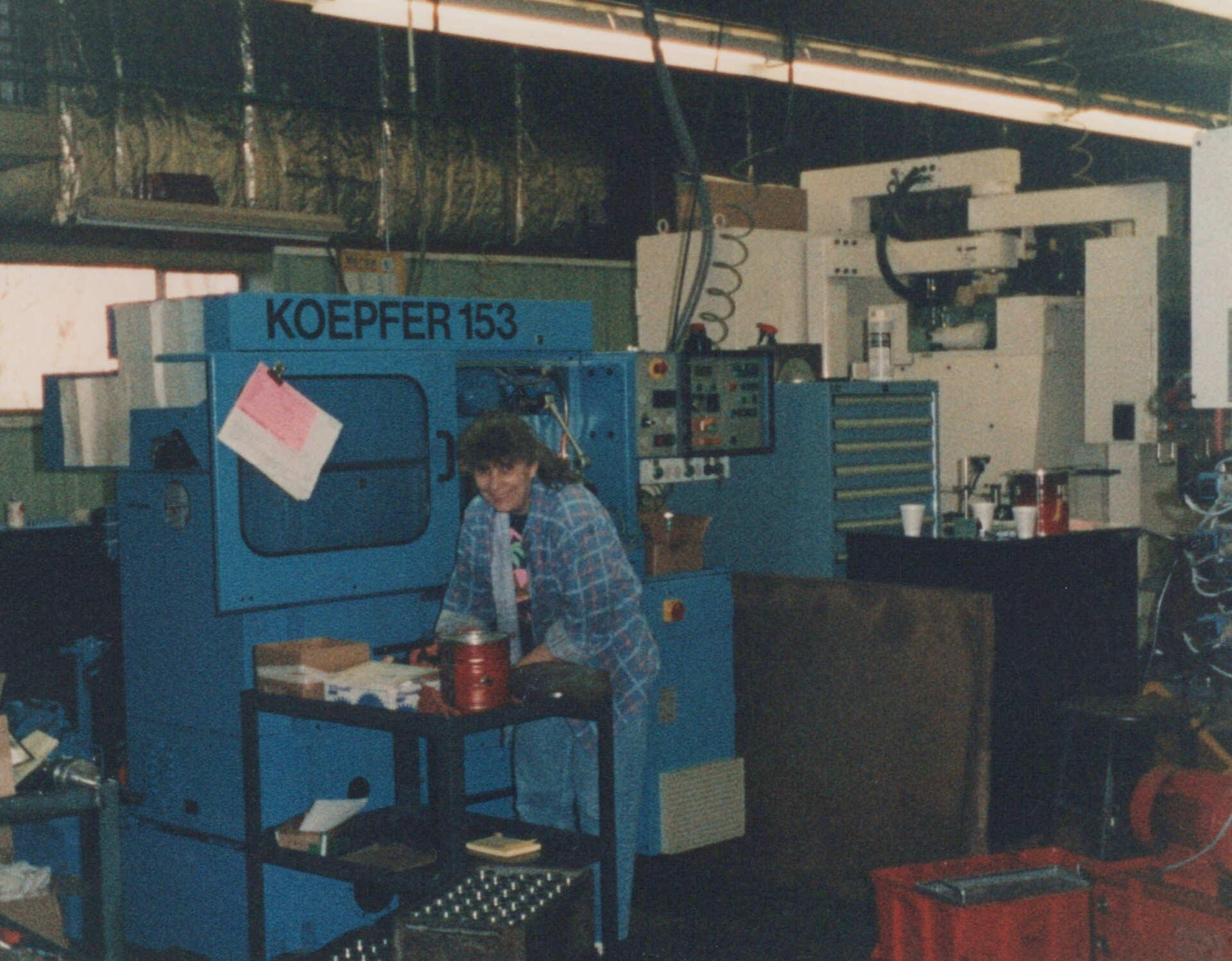

III. WHEN BUYING MACHINERY, BUY THE BEST.

The second-tier equipment will not hold up in the long run or command as much resale value. When determining the gear machine you wish to purchase, pick the machine appropriate and most efficient for the majority of your work. If 5 or 10% exceeds machine capacity, it is wiser to buy a second larger machine or farm out the work rather than purchase “Big Bertha” which does it all. Treat your equipment with care and good maintenance.

IV. OPTIMIZE YOUR MACHINERY FOR UTMOST QUALITY.

Explore your machine’s technical capabilities and measure the quality levels you can actually reach with each machine given good blanks and tooling. Then sort your jobs for quality levels to ensure you get the job on the appropriate determinations. It all boils down to you get what you pay for. Update your equipment regularly to take advantage of the latest technological developments in gear manufacturing. Benchmark yourselves against a peer gear company who does a better job than you do and try to reach or surpass their level.

V. LEARN FROM INSPECTION.

If possible, purchase analytical gear inspection equipment; it will serve several purposes. Analytical inspection makes your gears appear at least one grade worse than rolls testing against a master gear. For one, you will be able to evaluate better what is affecting your quality: blank, hob, tooling or machine. Number two, your set up people and operators will be able to see what effect their workmanship and efforts have on the finished product. Number three, it is a terrific sales tool which will dramatically improve your overall gear quality if properly used. Continual upgrading of inspection capabilities is necessary to gain ground in the market.

Although the gear business, as any other, is evolving, these constants remain true today. Take pride in the craftsmanship you control. Remember, accept no quality reduction at any step. Good luck in our fascinating industry and do not hesitate to call Forest City Gear if you encounter gear problems. Other gear companies and gear producers are some of our favorite customers!

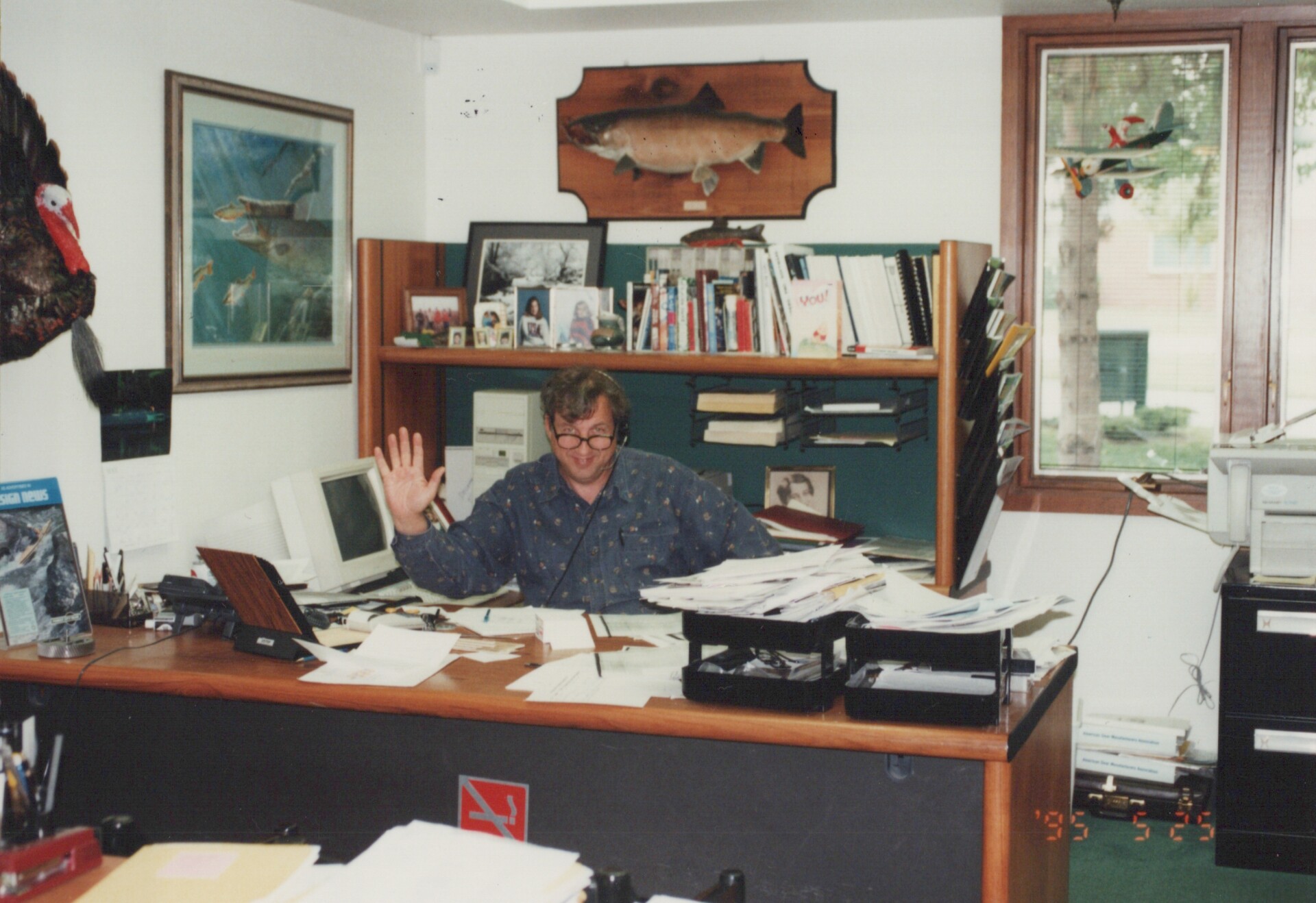

Fred Young, President of Forest City Gear

Recent News

April 30, 2025